This is a project which I have been working on alongside my father (Owen). His concept was to use a commonly available Ultrasonic Bath to clean vinyl records. This post will primarily serve to document the development of the prototyping of the machine. Please visit Owen’s website here and here for more information on the concept, operation and cleaning results.

The components were designed with batch production efficiency and shipping compactness in mind. I cut the initial prototype components from 1.5 mm stainless steel sheet using a waterjet cutter.

The parts were then folded on a manual sheet metal brake. Slots were designed into the component to aide in the alignment when folding manually.

The side components (motor mount and bearing rest) feature slotted holes to allow for minor adjustment of the spindle height and alignment.

The main frame is fitted with stainless steel m4 rivet nuts. I wanted to provide the end user with the easiest possible assembly and adjustment process. The use of rivet nuts mitigates the need for cumbersome nuts and washers, the machine can be assembled using only screwdrivers and hex keys.

First prototype shown in the images below, it only needed a few small adjustments to get the fit perfect on the next revision.

For the spindle, we chose to use an M6 threaded rod, this would allow the use of off the shelf M6 through hole knobs to clamp the records onto the spindle. The only challenge this would pose was how to get the threaded rod to connect with the motor. My solution was to mould a custom adaptor which would be glued to the threaded rod and feature a square drive to interface with the motor spindle.

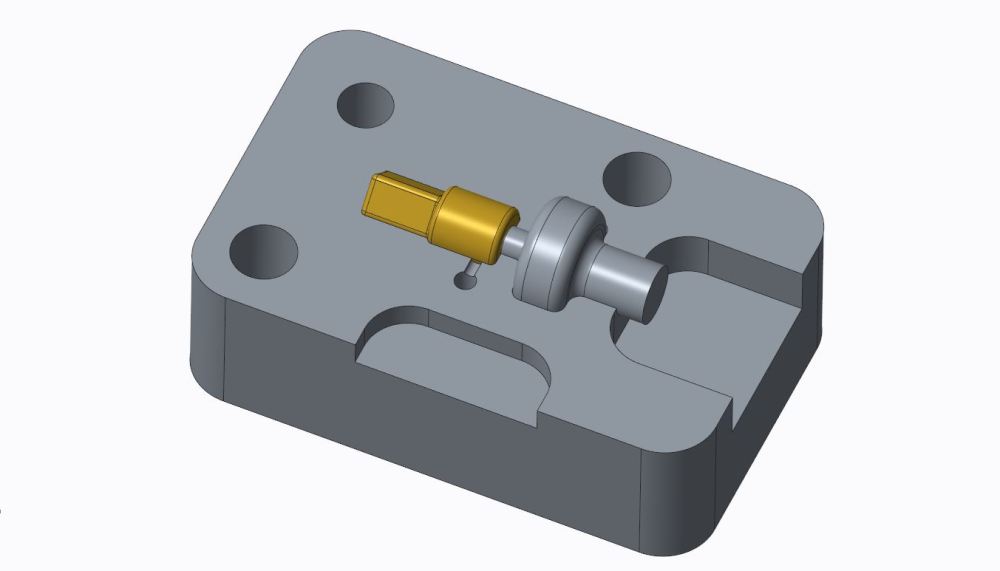

I proceeded to model the component in CAD and also design a simple injection mould tool.

The injection mould tool consists of 3 components; a Core and two Cavities. The Core was machined from steel and the Cavities from aluminium.

The Core component after machining in a 5-axis CNC mill.

The two cavity components with the core inserted is shown in the image below. In general, the injection moulding process requires that these two halves are fitted together and the whole assembly is loaded into a moulding machine. The machine then injects molten plastic (ABS in this case) into the mould where it cools and solidifies. The mould is removed and opened by hand in this case (production machines cycle automatically) and the component removed.

The process of setting up the injection moulding parameters.

A bag of freshly moulded components.

The image below shows the contents of the final kitset. In addition to the kitset, an ultrasonic bath and BBQ rotisserie motor are required to complete the machine.

- Ultrasonic Cleaner tank, model no. PS-30A

- BBQ rotisserie motor

The machine can comfortably clean 3 records per cycle, but others have also had success with 4 or more using thinner spacers.

We are very happy with how this project turned out, the general consensus is that the results of cleaning are very audible.

Quoted from Owen’s blog post:

“What I’m hearing consistently [after cleaning] is :

- More dynamic range, sounds ‘louder’, as if the stylus has more freedom tracking the groove.

- More High Frequency information – which sharpens ‘leading edges’, everything is snappier, faster, tauter, including bass frequencies.

- The above effects give rise to more ‘ambience’ – there is more ‘air’ & ‘sustain’ to musical notes.

- The cartridge often seems to track better – dynamic peaks seem to be ‘easier’, more ‘open’, have more freedom, less strain.

Overall, everything sounds more ‘live’, more ‘you are there’ more ‘in the room’.”

A lot more information and discussion of the development and use of this machine can be found on the Our DIY Ultrasonic Record Cleaner Thread (Stereo.net.au forum).