This is a picture of my completed “Sensitive Knurling Tool” built from the Hemmingway kit/plans. All parts (Except knurling wheels and screws) were machined manually and hand filed/finished.

Main body, milled, drilled and corner rounds filed.

Drilling symmetric rounds on arms

Drilling hole located partially on the part using sacrificial block

Reaming

Setup on rotary table to rough machine curves on arm components

Rough grinding rounds on belt sander

Finished using hand file and sane paper

Adapted drill press to spindle sander for finishing internal radii

Laser cut angle jig to locate arm component in vise.

Deep slot for knurling wheel milled

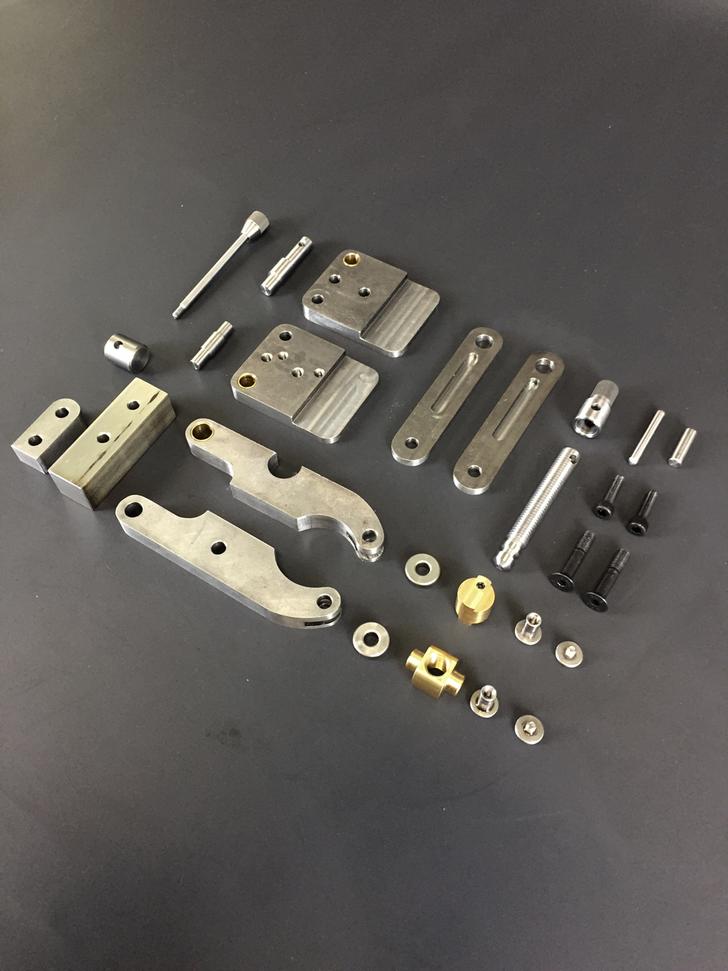

Some parts ready for test assembly.

Fitting cap and lever onto eccentric shaft

Quick split collar clamping fixture to hold part in lathe for second operation

Course adjust screw and assembly

I found that when adjusted to its larger settings, the feed adjuster side plates would often touch the side plates in the circled area. This caused the assembly to bind.

I fixed this by taking a little bit more material off the step on the inside of the side plates.

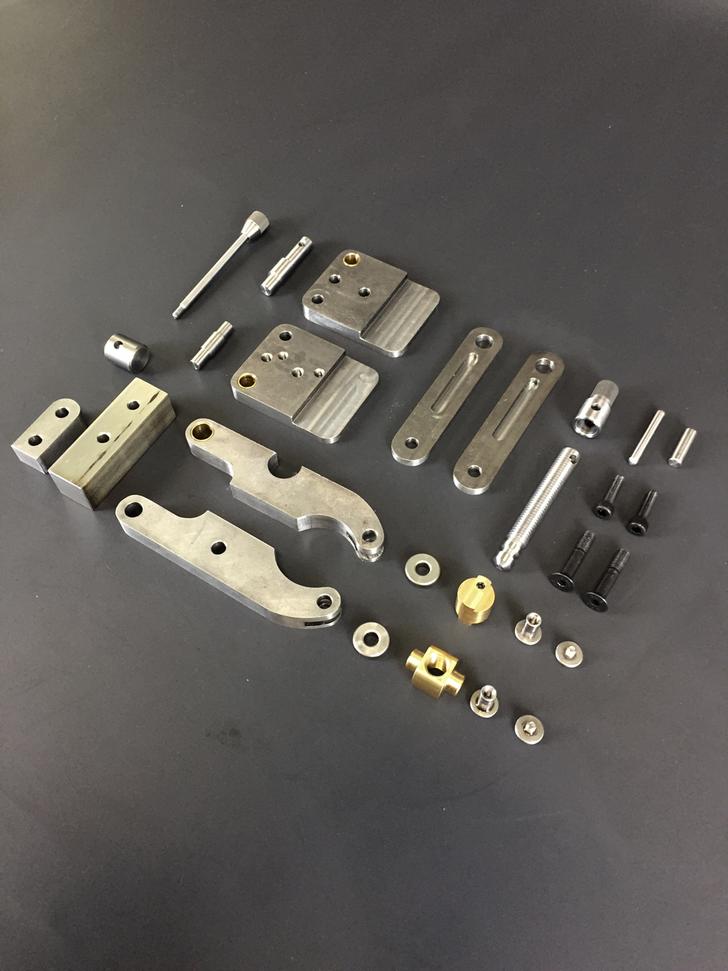

All the parts ready for assembly.

Here’s a link to a short video of me assembling the tool.

Here’s the first test knurls. I have a set of fine straight and fine diamond wheels.

the adapted drill press sander is clever!

LikeLiked by 1 person